Drum coating with hot vulcanization and egments on conveyor belt systems

METHOD OF DRUM COATING

1. HOT VULCANIZATION IN THE AUTOCLAVE at the factory

2. Segmental lining of operating, tension rollers with rubber coated metal segments is done in three ways:

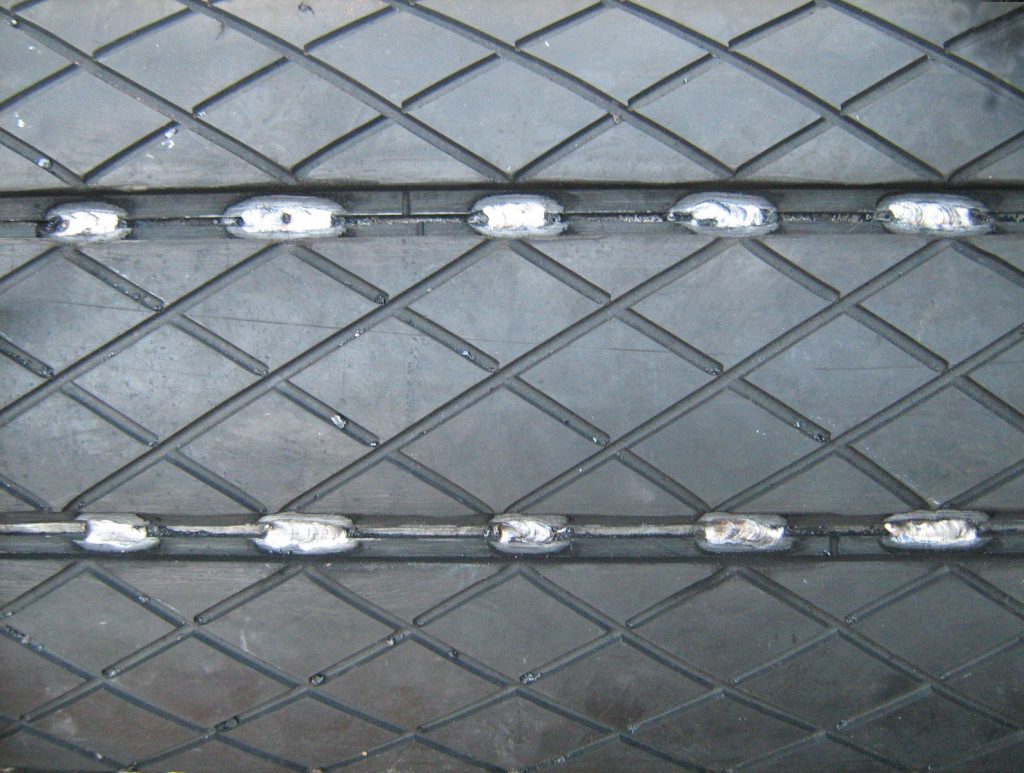

2.1. DIRECT WELDING ON SEGMENTS OF THE DRUM

Direct welding of segments on the mantle roller conveyor may be assembled in the field in a very short period of time.

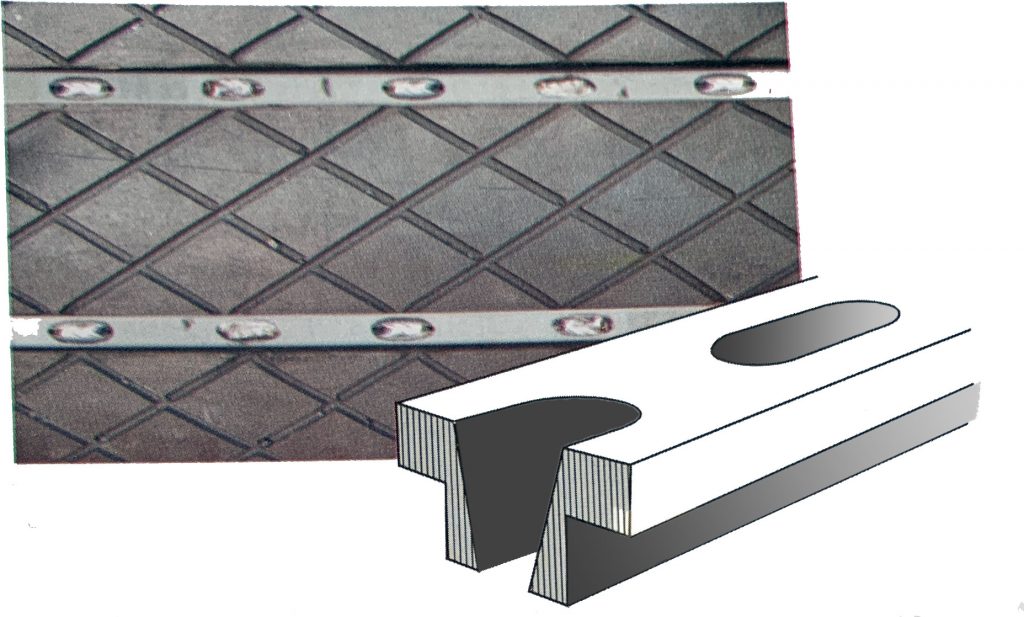

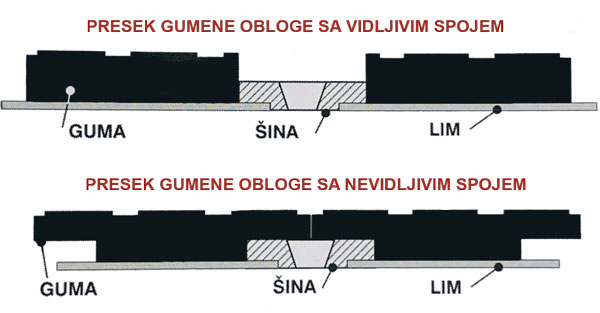

2.2 THE SYSTEM OF EXCHANGEABLE SEGMENTS WITH RAILS WELDED ON THE DRUM MANTLE

The system involves welding a “T” profiles on the mantle of the drum through which run rubberized metal segments. This system allows quick replacement wasted parts during operation.

2.3 SYSTEM OF EXCHANGEABLE SEGMENTS WITH RAILS WELDED ON THE DRUM MANTLE

Dimensions of segments

| Length of the tire (mm) | Length of segment (mm) | Width of segment (mm) |

|---|---|---|

| 10-40 | 1600-1800 | 150 |

The advantage of the coating roller segment relative to the hot vulcanization or cold autoclave and procedure

- On the field in a very short period of time.

- Time delays and losses minimized.

- Installation is performed with a much smaller number of editors.

- Reduced costs of assembly and disassembly of rollers from the conveyor.

- Eliminated pasted materials (especially tensioning rollers) .

- Doubled service life of the coating.

Send an inquiry with your needs!

We will do our best to meet all your requirements. If you need more information contact us before sending an inquiry.